Dresdener Grundwasserforschungszentrum e.V.

The entering and storing of gases in contaminated ground-water pipelines (gas sparging) is the current object of the research redevelopment in this field. The target of the research is the stimulation of biological, chemical and physical in-situ processes in pipelines with contaminated ground-water to enhance “natural attenuation” by special charging. The ground-water is treated by a special charging to add lacking reactive substances for the desirable processes (e.g. oxygene, nutrients) and also carbon substances for the control of the environment.

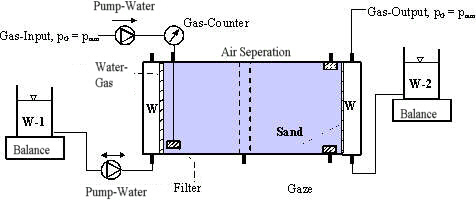

(scheme of a trial equipment for balancing the redevelopment of a contaminated ground-water pipeline. There is a Milligascounter-instrument in the middle of the photo).

Contact: www.dgfz.de, rgiese@dgfz.de

The Application of the Milligascounter for the research and restoring ground-water pipelines being contaminated by chemicals

The gas-production rate of cofermentations or the actual available gas production per kg dry matter either per kg organic dry matter is a key parameter of the process which cannot be calculated simply by the addition of individual gas production rates of single substances from literature tables.

For a mixture of substances, especially if they concern to the disposal of industrial wastes, the positive or negative effects on the gas production cannot be calculated by values of published literature. There might be deviations of several hundred percent.

Usually you can perform a “biological methane potential”-test (BMP) or a toxicity test in test flasks according to a special method or according to DIN 38414-S8 or VDI guidline 4630/4631, and possibly also according to ASTM 5210. For this you can also use small bioreactors, though the handling is somewhat laborious, but more exact.

Anyway, the question of gas-measurement still remains. Often you will use the so called Eudiometer (gas displaces simply the liquor in glass tubes). But the disadvantage of this method is that you have to refill it with water permanently. Closed vessels with pressure transducers to measure the over pressure represent another principle of gas measurement showing possibly negative or positive effects on the bacterial microflora according to the overpressure of CO2 or H2.

Therefore a miniaturized novel volumetric gasometer for small volumes of gas mixtures, especially biogas, has been developed at the Hamburg University of Applied Sciences. The inventor has used such self-made bigger devices for almost 20 years. With this Milligascounter® it is possible to measure biogas volumes of a few millilitres in a period of minutes or several weeks. By request the measurement (procedure) even can work online. With other words: online you can count by parallel management the gas production of 32 fermentation vessels with 1-10 l content each. The instruments are connected by a controller (a special impulse data logger) and a personal computer.

You can acquire the calibrated gas measurement-devices including fermentation device and attachments by the Dr. Ing. Ritter Apparatebau GmbH, Bochum (www.ritter.de) or by the company Bluesens GmbH, www.bluesens.de.

´

University of Applied Sciences Hamburg

´

University of Applied Sciences Hamburg